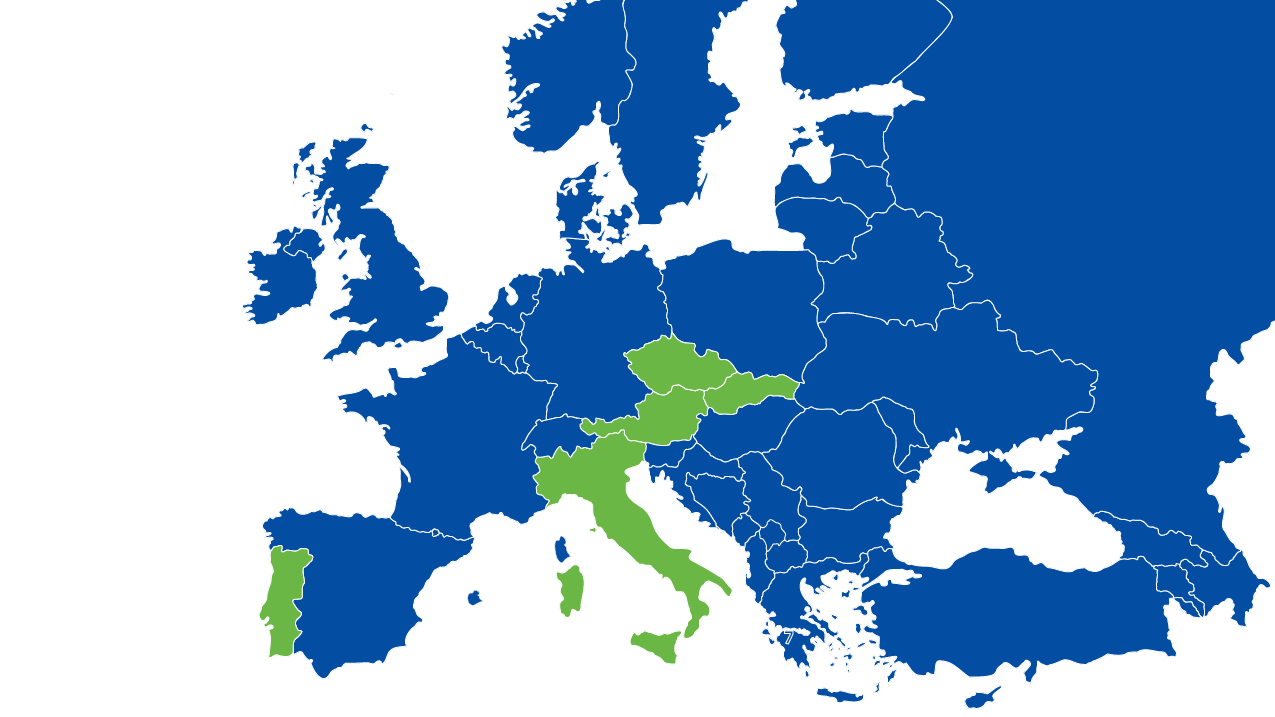

To accomplish the set objectives and to maximize impact, seven partners from five European countries merge their forces while completing the EIT knowledge triangle model for innovation and technology transfer and for access to networks of RIS based SMEs.

Consortium

STUBA offers the competencies of learning factory laboratories established at its Faculty of Mechanical Engineering which is a leading member of the Coordinating Centre of Professional Education and a partner of Slovakia based Industrial Innovation Cluster and the Slovak Maintenance Society (SMS). The education activities cover both academic teaching and the training of employees from the industry. The focus of the labs is on industrial automation, with emphasis on applications in mechanical engineering, such as control of machinery, using modern tools, methods and platforms of information technologies. Since 2016, the focus has been extended to the active elaboration of Industry 4.0 concepts, such as the development and integration of digital twins, machine condition monitoring and robot-assisted additive manufacturing.

CIIRC CTU concentrates on cutting-edge fundamental and applied research in a variety of fields in computer science and AI, manufacturing, energetics, smart cities, and a healthy society. CIIRC CTU builds a unique ecosystem for AI and advanced manufacturing, interconnecting industry and academia with the main European research and innovation networks. CIIRC CTU operates the Testbed for Industry 4.0 which is capable of providing courses on advanced manufacturing processes and robotics but also works as a testbed for knowledge/ technology transfer purposes. CIIRC CTU involves also the National Centre for Industry 4.0 (NCP4), which is a hub of the national ecosystem of universities, companies and associations involved in the smart production area. It also provides services like the Digital Innovation Hub for Industry 4.0. This optimal combination of own in-situ equipment and already established relations with the industrial companies makes CTU an appropriate partner for activities planned in FactoRIS.

FEUP – Faculty of Engineering of the University of Porto

DIGI2 – Digital and Intelligent industry Lab

FEUP offers the competencies of its Digital and Intelligent Industry Lab which is a part of the Research Center for Systems and Technologies. The lab develops R&D activities in advanced control concepts and systems, tools and technologies for a broad area of industrial applications including robotics, automation and advanced manufacturing systems. FEUP is also bringing the experience and results from the activity M-NEST-RIS (Network for Empowering People in Added-Value Manufacturing Systems and Technologies) funded by EIT-M under the 2020 business plan. Within FactoRIS II, FEUP contributes to the concept of learning factories by implementing new approaches related to cyber-physical production systems as well as by expanding the results of the FP7 ReBorn project (Innovative Reuse of modular knowledge Based devices and technologies for Old, Renewed and New factories) towards RIS SMEs.

ART-ER – Attractiveness Research Territory

ART-ER is a consortium among the Emilia-Romagna universities, research centres and the Regional government, with cca. 200 employees. It is a Digital Innovation Hub recognized by the National government, providing services for companies mainly belonging to agrifood, mechatronics and motorists, health and welfare sectors. ART-ER is a member/partner of a number of European networks, including EIT Manufacturing, EIT Climate, EIT Raw Materials, EFFRA, and EEN. ART-ER provides a valuable link to manufacturing SMEs and their digital maturity assessment, as well as experience with the Clust-ER Communities (research centres, companies, training institutions) who share ideas, skills, tools, and resources to support the competitiveness of production systems in Emilia-Romagna.

UniMORE – University of Modena and Reggio Emilia

UniMORE offers the competences and research facilities of its X-in-the-Loop advanced Simulation lab (XiLab), which is a part of the Interdepartmental Centre for Automotive and Advanced Mechanics (INTERMECH MO.RE), purposely created to promote both cutting-edge industry-driven research and technology transfer between academia and industry. The XiLab focuses on Human-Centered Design and Simulation for Industry 4.0, thanks to the use of VR technologies, human simulation and monitoring tools and strategies for adaptive interfaces. XiLab large area (6x2m) VR Cadwall offers an immersive 3D experience for experiencing complex systems and simulating their behavior within an interactive virtual environment, thus promoting collaborative approaches. XiLab has developed many technology transfer contracts with important companies and European research projects (AREUS, ColRobot, Xmanai, Penelope, just to name the more relevant with the current topics) based on VR-AR humancentric technologies and methods to train high-qualified Industry 4.0 operators.

IIC – Industry Innovation Cluster

IIC was established in 2017 under the patronage of the French-Slovak Chamber of Commerce, with the ambition to become an accelerator for innovation in Slovak industry. IIC aims to bring together companies that are leaders in the Slovak industry and want to move Slovakia forward in competitiveness and innovations. IIC is a founding member of Digital Innovation Hub – Slovak Centre for Digital Innovations (SCDI), which helps companies become more competitive with regard to their business/production processes, products or services using digital technologies. It provides access to technical expertise and experimentation, innovation services, such as financing advice, training and skills development that are needed for a successful digital transformation.

TU Wien – Technische Universität Wien / Vienna University of Technology

TUW contributes with both the infrastructure of its learning and demonstration factory, and the experience in training for students and employees from industry. Since 2017, TU Wien successfully runs its own Pilotfabrik Industrie 4.0, and can thus provide valuable experience in Industry 4.0 topics, such as digital assistance systems, human-machine collaboration and optimization of process and product quality. It is also a founding partner of the LIFT Europe consortium, which builds a broad learning factories network ecosystem mostly in developed European countries. Within FactoRIS II, TU Wien offers the competences of three departments of mechanical engineering (production engineering, management sciences, design and mechanical engineering informatics). As a partner experienced in supporting Austrian SMEs in their digital transformation, it will contributes to the project by supporting implementation of learning factories projects at partner facilities in RIS countries. www.pilotfabrik.at/